Description

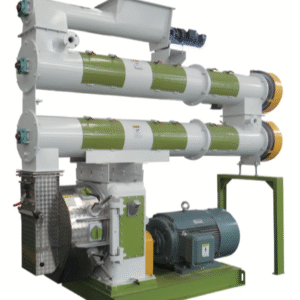

Technical Specifications & Design Innovation

Dual-Shaft Conditioning System

-

Primary Shaft: High-speed mixing (200-400 RPM) for rapid heat transfer

-

Secondary Shaft: Slow-speed kneading (50-120 RPM) for extended retention

-

Shaft Configuration: Counter-rotating with adjustable clearance

-

Power Requirements: 30-110 kW total drive capacity

Enhanced Conditioning Parameters

-

Retention Time: 120-300 seconds (adjustable based on moisture content)

-

Temperature Control: 85-95°C optimal for fiber modification

-

Steam Addition: 5-12% dry saturated steam at 4-7 bar

-

Liquid Binding Agents: 2-5% addition capability

Specialized Pelletizing Components

-

Die Design: Extended thickness (60-150 mm) for high-fiber formulations

-

Die Materials: Tungsten carbide inserts for abrasive resistance

-

Roller Configuration: Deep-grooved design for enhanced grip

-

Compression Ratio: 1:8 to 1:15 (adjustable for different fiber levels)

Processing Advantages for Distiller’s Grains

Moisture Management

-

Handles 25-35% moisture content in raw distiller’s grains

-

Reduces final pellet moisture to 12-14%

-

Maintains consistent moisture distribution (±0.8%)

Fiber Modification

-

Increases soluble fiber content by 15-25%

-

Improves starch availability through fiber encapsulation breakdown

-

Enhances pellet binding through natural fiber lignification

Nutritional Preservation

-

Maintains protein quality during thermal processing

-

Reduces microbial contamination through pasteurization

-

Preserves fat content while improving stability

Performance Specifications by Animal Category

| Animal Type | Max DDGS Inclusion | Pellet Durability | Production Rate | Energy Consumption |

|---|---|---|---|---|

| Dairy Cattle | 40% | 90-92% | 8-18 t/h | 18-25 kWh/t |

| Beef Cattle | 35% | 88-90% | 10-20 t/h | 16-22 kWh/t |

| Swine | 30% | 85-88% | 6-15 t/h | 20-28 kWh/t |

| Poultry | 25% | 82-85% | 5-12 t/h | 22-30 kWh/t |

Quality Assurance Metrics:

-

Pellet Durability Index (PDI): 82-92%

-

Fines Generation: 4-8%

-

Starch Gelatinization: 35-50%

-

Fiber Digestibility Improvement: 12-18%

Economic & Operational Benefits

Cost Reduction Advantages

-

Raw Material Savings: 15-30% compared to traditional ingredients

-

Energy Efficiency: 20-35% better than single-shaft systems

-

Production Capacity: 25-40% higher throughput

-

Maintenance Costs: 15-25% reduction through balanced wear

Nutritional Economics

-

Improved feed conversion ratios (3-8% enhancement)

-

Reduced feed costs ($15-45/ton savings)

-

Enhanced animal performance through better nutrient utilization

-

Increased formulation flexibility

Case Study – Midwest Feed Mill:

After implementing double-shaft technology for DDGS pelleting:

-

Production capacity increased from 12 to 16 t/h

-

Pellet quality improved (PDI from 80% to 88%)

-

Energy consumption reduced by 24%

-

Formulation costs decreased by $28/ton

Technical Innovations & Custom Features

Intelligent Control Systems

-

Moisture sensors for real-time adjustment

-

Temperature profiling for optimal fiber modification

-

Automated recipe management for different DDGS sources

-

Predictive maintenance monitoring

Specialized Component Design

-

Abrasion-resistant alloys for extended component life

-

Advanced sealing systems for high-moisture environments

-

Custom die geometries for specific fiber characteristics

-

Enhanced cooling systems for temperature-sensitive nutrients

Process Integration

-

Pre-breaking systems for lump reduction

-

Liquid application systems for binders and additives

-

Automated quality monitoring

-

Data integration with plant management systems

Operational Guidelines & Best Practices

Raw Material Handling

-

Consistent moisture monitoring of incoming DDGS

-

Proper storage conditions to prevent spoilage

-

Regular testing for nutritional consistency

-

Strategic blending with other ingredients

Process Optimization

-

Optimal steam quality and pressure maintenance

-

Regular die and roller inspection

-

Proper conditioning temperature control

-

Consistent mixing and retention time management

Quality Control Protocols

-

Regular pellet durability testing

-

Moisture content verification

-

Nutritional analysis compliance

-

Microbial safety monitoring

Sustainability Impact & Future Development

Environmental Benefits

-

Reduces waste from ethanol production

-

Lowers carbon footprint through local ingredient utilization

-

Decreases land use for feed production

-

Enhances circular economy in biofuel operations

Technology Evolution

-

AI-driven process optimization

-

Advanced sensor technology for real-time quality control

-

Integration with renewable energy sources

-

Enhanced automation for consistent quality

Market Adaptation

-

Increasing DDGS inclusion rates in various animal diets

-

Expansion to other high-fiber co-products

-

Global technology transfer to emerging markets

-

Customization for specific regional ingredients

Reviews

There are no reviews yet.