Description

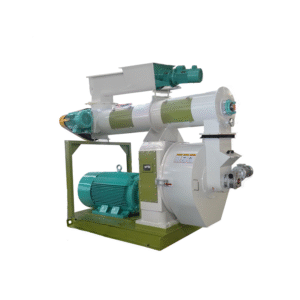

Technical Specifications & Design Features

Drive & Power Configuration

-

Main Motor Power: 22-160 kW (30-215 HP) vertical mount motors

-

Gear System: Helical gear reducers with vertical output shafts

-

Drive Arrangement: Top-mounted or integrated motor configurations

-

Control Systems: VFD options for speed optimization

Pelletizing Components

-

Die Orientation: Vertical die mounting with horizontal material flow

-

Die Diameter: 300-800 mm (compact to medium capacity)

-

Die Thickness: 35-80 mm (standard L/D ratios)

-

Roller Configuration: 2 or 3 rollers with specialized vertical mounting

Capacity & Performance

-

Production Capacity: 0.5-5 t/h (application dependent)

-

Power Consumption: 30-55 kWh/ton

-

Noise Levels: 78-85 dB (typically lower than horizontal mills)

-

Footprint Efficiency: 40-60% space savings vs equivalent horizontal mills

Application-Specific Performance

| Application | Optimal Capacity | Typical Die Size | Pellet Quality | Special Advantages |

|---|---|---|---|---|

| Small Biomass Production | 1-3 t/h | 400-600mm | 92-96% PDI | Easy die change, low installation cost |

| Laboratory & Research | 0.5-1.5 t/h | 300-400mm | 90-95% PDI | Quick formula changes, minimal material requirement |

| Specialty Feed Production | 1-4 t/h | 450-650mm | 94-97% PDI | Good for heat-sensitive formulas |

| Pilot Plant Operations | 0.8-2.5 t/h | 350-500mm | 91-96% PDI | Flexible operation, easy monitoring |

Key Operational Characteristics:

-

Material Feeding: Gravity-assisted in some designs

-

Heat Distribution: Potentially more uniform in vertical configuration

-

Accessibility: Easier access to die and rollers for maintenance

-

Installation: Simplified foundation requirements

Advanced Engineering Features

Vertical Compression System

-

Gravity Utilization: Natural material flow in some designs

-

Pressure Distribution: Optimized roller pressure in vertical plane

-

Die Design: Specialized vertical die patterns and hole configurations

-

Roller Mounting: Enhanced bearing systems for vertical loading

Material Handling & Feeding

-

Feed Hopper: Designed for consistent vertical material flow

-

Distribution System: Even material distribution across die surface

-

Level Control: Automatic feed rate adjustment

-

Bridge Breaking: Mechanical or pneumatic anti-bridging systems

Maintenance & Service Features

-

Quick Die Change: Simplified die replacement procedures

-

Roller Access: Easy roller inspection and replacement

-

Clean-out: Enhanced clean-out capabilities

-

Lubrication: Centralized or automatic lubrication systems

Industry Applications & Operational Benefits

Small-Scale Biomass Operations

Vertical pellet mills excel in small to medium biomass operations where space is limited and production requirements are moderate. The compact design and easier maintenance make them ideal for farm-based pellet production or small commercial operations. One agricultural cooperative documented 95% availability while producing 2,000 tons annually of straw pellets in a confined facility space.

Research & Development Facilities

The accessibility and flexibility of vertical mills make them perfect for research applications where frequent formula changes and process observation are required. A university research program successfully developed 15 different biomass formulations using a single vertical mill, with changeover times under 30 minutes between recipes.

Specialty Feed Manufacturing

For manufacturers producing specialized feeds in smaller batches, vertical mills provide the flexibility needed for frequent product changes while maintaining consistent pellet quality. A specialty feed company reduced changeover time by 60% compared to their previous horizontal mill while maintaining 96% pellet durability across 12 different formulations.

Pilot Plants & Technology Development

The visibility and accessibility of the pelletizing process in vertical mills make them ideal for process development and demonstration. A equipment manufacturer uses vertical mills for customer demonstrations and process testing, providing clear observation of the pellet formation process.

Operational Economics & Maintenance

Cost Analysis

-

Equipment Investment: $45,000-$150,000 (capacity dependent)

-

Installation Costs: 15-25% of equipment cost (reduced foundation requirements)

-

Energy Consumption: $15-$35 per ton produced

-

Maintenance Costs: Typically 15-25% lower than equivalent horizontal mills

Efficiency Metrics

-

Space Utilization: 40-60% better footprint efficiency

-

Labor Efficiency: Reduced maintenance time and effort

-

Material Utilization: 96-98% conversion efficiency

-

Operational Flexibility: Quick changeover between products

Maintenance Advantages

-

Reduced Downtime: Faster die and roller changes

-

Simplified Service: Easier access to critical components

-

Lower Labor: Reduced maintenance time requirements

-

Component Life: Comparable to horizontal mill components

Comparative Analysis: Vertical vs Horizontal Mills

Advantages of Vertical Design

-

Space Efficiency: Significantly smaller footprint

-

Accessibility: Better access for maintenance and observation

-

Installation: Simplified installation requirements

-

Cost: Generally lower initial investment for comparable capacity

Considerations for Vertical Mills

-

Capacity Limitations: Typically lower maximum capacity than large horizontal mills

-

Material Handling: Potential challenges with certain material types

-

Industry Acceptance: Less established in some traditional industries

-

Component Availability: May have fewer supplier options than horizontal mills

Future Development & Market Trends

Technology Evolution

-

Enhanced Control Systems: Improved automation and monitoring

-

Advanced Materials: Better wear components for vertical configuration

-

Hybrid Designs: Combining advantages of vertical and horizontal systems

-

Smart Features: IoT connectivity and predictive maintenance

Market Directions

-

Distributed Production: Growth in small-scale localized pellet production

-

Specialization: Increased demand for application-specific designs

-

Sustainability: Focus on energy efficiency and reduced environmental impact

-

Globalization: Expansion into developing markets where space constraints are significant

Reviews

There are no reviews yet.