Description

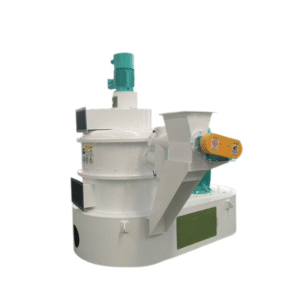

YHM60 Series Hammer Mill

【Basic Features】

1.Available raw material: wood bricks, shavings, straw, peanut shell, palm shell, cotton seed, bamboo dust, rice husk,elephant grass, sugar cane, pulp, olive dust and so on.

2.Siemens motor and SKF bearing.

3.Grinding chamber separation device optional, with high grinding efficiency.

4.U-shape grinding groove at the bottom of grinding chamber, with improvement of grinding efficiency of 50%-80%.

5.Unique Feeding Design, the feeding inlet is made at the side of the device to make feeding easily.

6.The shell is welded by steel plate, the site in the crush room which connects to the materials all use the wearable and commutative parts and double wear plate.

7. The motor and rotor are installed in the same heavy-duty base, using coupling direct drive, the rotor are checked by dynamic balance, and can work forward and reverse, the hammers are arranged symmetrically.

8.Two kinds of gap between beaters and screeners through changing position of beater are used for coarse and fine grinding.

9.The smaller gap between beater and screeners can be used for grinding coarse and fine materials.

【Working principle】

The material needs to be ground be fed into the top intake port through the feeding device which matches this hammer mill, enters into the grinding room from the left or right side through intake direction plate. Under the beating of high speed rotating hammer and the rubbing effect of screen, material is grinded gradually, and

discharged from the seat discharging port through screen holes under the effect of centrifugal force and airflow.

HENGMU passed the audit of ISO9001 quality system and all finished products meet the CE standard.

We insist on “Quality is the soul of company“. Our processing equipments are used the most up-to-date

CNC Machine Center. Heat treatment is conducted “in-house”assuring consistent and strict quality standards.

Non-dust workshop are highly recognized by overseas clients. YONGLI owns a dynamic R&D team, which

follows the principle of “Motive through Innovation, Stand through Quality, Develop through Technology”

leading us to supply convenient turn-key projects to clients.

Reviews

There are no reviews yet.